Our presented ranges of those items sq. evaluate appreciated for top-quality quality, sturdiness and resistance to rust.

Generally, the price for that mildew or perhaps the tooling procedure might be separated from the overall expense of the injection molding course of action. The injection mould Expense will be payable through the First phase of your respective injection molding procedure, once the blueprint style for your mould continues to be submitted to us. The mold creation procedure could consider a while to complete. It is going to rely on the complexity and options of your mold. Also, the manufacturing for that plastic parts is often began only once the mould is ready. You may use the two quick producing or typical manufacturing procedures with the mildew generation, Every of that will also vary in selling price. Vital Elements that Will Have an affect on the Customized Injection Molding Value ● The readiness of one's style blueprint, in addition to the complexity or intricacy of your solution design and style. ● Raw materials you will use for the plastic products and mold, such as the material sort and quality or quality. ● The kind of producing technologies to work with, for instance speedy producing or typical manufacturing. ● The tooling method and different facets of the mold, together with design, options, materials, and the like. ● Your project needs, which involve the deadline you established for it. Various supplemental processes involving the creation of your respective plastic merchandise, such as branding, pad printing, and so on.

Things to think about when using brass inserts in plastic injection molding Here are a few critical elements to look at when applying brass inserts in plastic injection molding:

Aspects Brass moulding inserts absolutely are a fastener that provides a secure and trustworthy keep in the plastic software.

What genuinely sets us aside is our ability to provide worth-extra services that our opponents can’t. Search our complete suite of pro abilities.

Regularly Questioned Concerns What Is Injection Molding? Injection molding is usually a forming method by injecting molten product into a mold to make elements in smaller volumes to one,000,000 +. It could be executed with numerous elements such Brass Injection Molding Inserts as elastomers, glasses, confections, thermoplastic, thermosetting polymers, and metals(for which the method is named die casting). Precisely what is Plastic Injection Molding? Plastic injection molding is actually a branch of injection molding. This is a Price tag-productive and responsible method to provide strong and plastic pieces and goods in any volume. The method requires substantial strain to drive a molten liquid polymer right into a hollow mold. It truly is faraway from the mold when the polymer is cooled and solidified, as well as cycle repeats.

Strength: Brass is a solid and durable metallic that may be immune to impression and have on. When employed as inserts in plastic injection molding, brass can assist to raise the strength and toughness in the completed element.

Bushings and sleeves are An additional fantastic way to enhance part longevity for mating elements that need to have far more abrasion resistance because of transferring areas.

If you need some compact quantity areas(including some basic plastic moulding trim) devoid of superb beauty and steady dimensions, Do-it-yourself injection molding to mould these plastic moulding trim could be a solution.

Group Rapid invests a number of exact devices to meet your any volume generation requirements. Often a well timed report.

Speak with us about developing a personalized section, tool or method. We are Outfitted to assist you to to tackle and clear up your most significant engineering troubles.

We're your producing associate to scale tasks to output. Get total program management that has a workforce who can tailor our abilities to improve cost, amount, and quality Charge of your creation purchase.

Our varied variety of devices, scaling around 1300 tonnes, makes it possible for us to cater to some multitude of jobs/programs. Regardless of whether you need products weighing 1 gram or 10Kg, We've got the aptitude and potential to mould to your preferences.

"What I really favored about your company was the engineering interface. Your electrical power place structure by using electronic mail had numerous options so I had been ready to make the smallest modifications to the look as well as the advancements have been executed precisely as I desired. I hardly ever had that level of Regulate just before. Your prices had been also pretty eye-catching."

Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Shane West Then & Now!

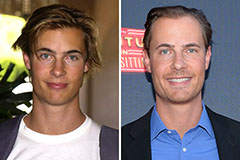

Shane West Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now!